This 12 V linear actuator can be used in a variety of heavy-duty applications. The motor has 5:1 reduction gearbox that gives the actuator a dynamic load rating of 34 lbs (15 kg) and a maximum speed of 1.7 in/s (4.3 cm/s), and it is rated to withstand up to 450 lbs when not moving. Limit switches at each end make the actuator easy to control over its full range of motion, and the worm drive ensures that the shaft will hold its position even when unpowered. This version has a 12-inch stroke and no potentiometer.

|

| Concentric linear actuator without feedback, opened to show gears. |

|---|

The LD Series of linear actuators by Concentric International (formerly Iowa Export-Import) are 12V DC gearmotors that use a worm drive to move a shaft back and forth along its length. The worm drive ensures that the shaft will hold its position even when unpowered. Two limits switches safely stop the motor at either end of its range, while diodes allow it to reverse direction after reaching a limit point. The actuators are mostly metal, and the entire case is sealed to protect against dust and water (rated IP63).

|

| Connecting the bracket to one end of a Concentric LD linear actuator. |

|---|

The Concentric LD series linear actuators are available in a variety of lengths and with optional potentiometers that are linked to the shaft position, for use in feedback systems. Several lengths are also available in two gear ratios: 5:1 and 20:1. The 5:1 versions have lower load ratings—34 lbs dynamic, 450 lbs static—but allow for higher speeds, up to 1.7 in/s. The 20:1 versions are slower—up to 0.5 in/s—but are rated for dynamic loads up to 110 lbs and static loads up to 500 lbs.

| Stroke length |

20:1 | 20:1 w/feedback | 5:1 | 5:1 w/feedback |

|---|---|---|---|---|

| 2” | LACT2-12V-20 | LACT2P-12V-20 | ||

| 4” | LACT4-12V-20 | LACT4P-12V-20 | LACT4-12V-5 | LACT4P-12V-5 |

| 6” | LACT6-12V-20 | LACT6P-12V-20 | ||

| 8” | LACT8-12V-20 | LACT8P-12V-20 | ||

| 10” | LACT10-12V-20 | LACT10P-12V-20 | ||

| 12” | LACT12-12V-20 | LACT12P-12V-20 | LACT12-12V-5 | LACT12P-12V-5 |

We also have generic linear actuators that can generally be used as less expensive alternatives to the ones from Concentric; the table on our linear actuator category page can help you find the actuator with the combination of speed and force that best meets your project’s requirements.

Mounting brackets are available for attaching the actuators to a structure; two are required for each actuator. Our bracket for generic linear actuators also work with the LD actuators, although they are a little loose.

|

| Concentric linear actuator with feedback, 4" Stroke (LACT4P), shaft fully extended. |

|---|

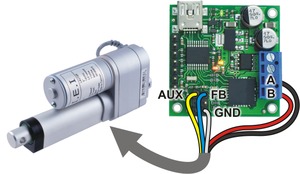

To test-drive the actuator, simply connect a power source of up to 12 V to the motor leads. Reversing the applied voltage will reverse the direction of motion. A motor controller or motor driver is required for electronic speed and direction control. We recommend our Jrk Motor Controllers for use with the feedback actuators and the Pololu Simple Motor Controller 18v7 for controlling the actuators without feedback, though many of our other motor controllers and motor drivers are capable of powering this actuator.

These actuators have a stall current of 10 A at 12 V, but they will, on average, draw far less than this when used within their load ratings. They draw around 500 mA with no load an can exceed 3 A at their maximum rated dynamic load, so we have found they generally work well with our lower-power jrk 21v3 motor controller with feedback (see the bottom of this page for more information using this controller for closed-loop linear actuator position control). Note, however, that the actuators can briefly draw close to their full stall current when abruptly started or on a sudden change of direction. Such current spikes can be dampened if you take steps to limit the acceleration of the actuator (many of our motor controllers offer optional acceleration limiting).

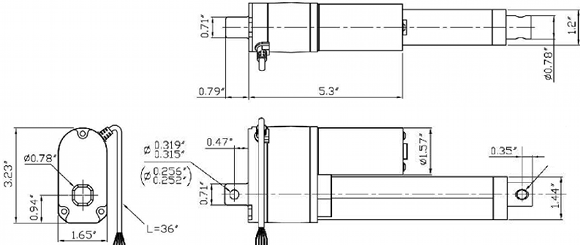

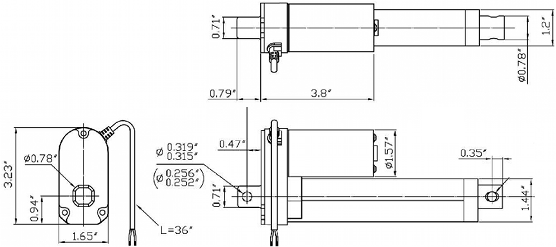

Diagrams of the linear actuators are shown below. The versions that include potentiometers have a larger gearbox, so their overall size and weight is larger. For more detailed information, including the retracted and extended lengths of each version, see the appropriate datasheet (click the Resources tab above).

|

| Dimensional drawing for the Concentric LD linear actuators with feedback. |

|---|

|

| Dimensional drawing for the Concentric LD linear actuators without feedback. |

|---|

Each actuator has a 3-foot-long cable. On actuators with feedback, this cable is terminated with special female connectors as shown in the left picture below, one for the three potentiometer leads and another for the two power leads. These connectors match male versions on the extension cable for LD linear actuators. Actuator versions without feedback have two unterminated, stripped power leads as shown in the right picture below. Linear actuators without feedback do not have cables that are compatible with the linear actuator extension cable.

|

|

The feedback feature included with our jrk motor controllers make them a great solution for precisely controlling our linear actuators with feedback. Our settings file for the jrk configuration utility makes setup easy, eliminating the need to calibrate the feedback and tune the PID constants. To get started, follow the steps below:

|

| Connecting a LACTxP linear actuator with feedback to a jrk 21v3 motor controller. |

|---|

While this setting file gives precise control over most of an actuator’s range, you might find decreased performance very near the extremes due to the limit switches. If your project requires better control near the actuator’s limits, you might need to recalibrate the feedback settings for your particular actuator.

Producent BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Polska sprzedaz@kamami.pl 22 767 36 20

Osoba odpowiedzialna BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Polska sprzedaz@kamami.pl 22 767 36 20

Siłownik liniowy LACT8-12V-20 z wysuwem 20,3 cm i przekładnią 20:1 oferuje siłę 500 N i stabilność pozycji bez zasilania. Model bez sprzężenia zwrotnego, przeznaczony do zastosowań wymagających prostego, ale niezawodnego sterowania ruchem.

Brak towaru

Siłownik liniowy LACT8P-12V-20 z wysuwem 20,3 cm i przekładnią 20:1 zapewnia siłę 500 N oraz sygnał sprzężenia zwrotnego do precyzyjnej kontroli położenia. Zintegrowane wyłączniki krańcowe i napęd ślimakowy umożliwiają niezawodną pracę w układach automatyki i sterowania.

Siłownik liniowy LACT10-12V-20 z wysuwem 25,4 cm i przekładnią 20:1 oferuje siłę 500 N i stabilność pozycji bez potrzeby zasilania. Rozwiązanie bez sprzężenia zwrotnego, odpowiednie do zastosowań w systemach automatyki i mechanizmach liniowych.

Brak towaru

Siłownik liniowy LACT12-12V-20 z wysuwem 30,5 cm i przekładnią 20:1 osiąga siłę 500 N i prędkość 12,3 mm/s. Model bez sprzężenia zwrotnego, przeznaczony do zastosowań, w których liczy się niezawodność i kontrola końcowych pozycji skoku.

Brak towaru

Brak towaru

Brak towaru

42" Extension Cable for Concentric LD Linear Actuators

Solenoid liniowy o nominalnym napięciu pracy 36 V. Pozwala na wywołanie ruchu liniowego w celu przesuwania elementów lub sterowania przełącznikami i dźwigniami. SparkFun ROB-10391

Brak towaru

Drut ze stopu niklowo-tytanowego o długości 30 cm z pamięcią kształtu. Kiedy jest w formie martenzytycznej, może być dowolnie wyginany odkształcany. Po przyłożeniu natężenia prądu o wartości ok. 200 mA lub ogrzaniu do temperatury 100°C drut wraca do pierwotnego kształtu. SparkFun COM-11899

Drut ze stopu niklowo-tytanowego o długości 30 cm z pamięcią kształtu. Kiedy jest w formie martenzytycznej, może być dowolnie wyginany odkształcany. Po przyłożeniu natężenia prądu o wartości ok. 1,5A lub ogrzaniu do temperatury 100°C drut wraca do pierwotnego kształtu. SparkFun COM-11900

Siłownik liniowy średniego obciążenia (medium-duty), pozwala podnosić obciążenie do 100 kgf (1000 N) i wytrzymywać obciążenie statyczne do 450 kgf (4500 N), nominalny wysuw siłownika wynosi 10 cm. Napięcie zasilania wynosi 12 V. Ta wersja siłownika posiada wbudowany potencjometr, co na odczyt pozycji siłownika lub np. implementacje sprzężenia zwrotnego. Pololu 3612

Brak towaru

Siłownik liniowy średniego obciążenia (medium-duty), pozwala podnosić obciążenie do 100 kgf (1000 N) i wytrzymywać obciążenie statyczne do 450 kgf (4500 N), nominalny wysuw siłownika wynosi 25 cm. Napięcie zasilania wynosi 12 V. Ta wersja siłownika posiada wbudowany potencjometr, co na odczyt pozycji siłownika lub np. implementacje sprzężenia zwrotnego. Pololu 3618

Brak towaru

Solenoid liniowy o nominalnym napięciu pracy 5 V. Pozwala na wywołanie ruchu liniowego w celu przesuwania elementów lub sterowania przełącznikami i dźwigniami. JF-0530B

Brak towaru

Miniaturowy siłownik liniowy, który oferuje posuw do 50 mm przy prędkości od 3 do 5 mm/s. Ma zabudowany silnik i jest zasilany napięciem od 3 do 6 V

Brak towaru

Miniaturowy siłownik liniowy, który oferuje posuw do 130 mm przy prędkości od 3 do 5 mm/s. Ma zabudowany silnik i jest zasilany napięciem od 3 do 6 V

Brak towaru

Siłownik liniowy 12 V DC, przeznaczony do precyzyjnych zastosowań w automatyce, robotyce, projektach DIY oraz lekkich aplikacjach przemysłowych. Oferuje skok nominalny 20 cm i dynamiczne obciążenie do 15 kgf, przy zachowaniu stabilności statycznej nawet bez zasilania. Wbudowane wyłączniki krańcowe oraz potencjometr sprzężenia zwrotnego pozwalają na bezpieczne i dokładne sterowanie położeniem tłoka, a aluminiowa obudowa z klasą szczelności IP65 zapewnia odporność na kurz i wilgoć. Siłownik pracuje płynnie i cicho z prędkością do 43,9 mm/s bez obciążenia, a zmianę kierunku osiąga się przez odwrócenie polaryzacji napięcia. Pololu 2323

Brak towaru