865,48 zł Netto

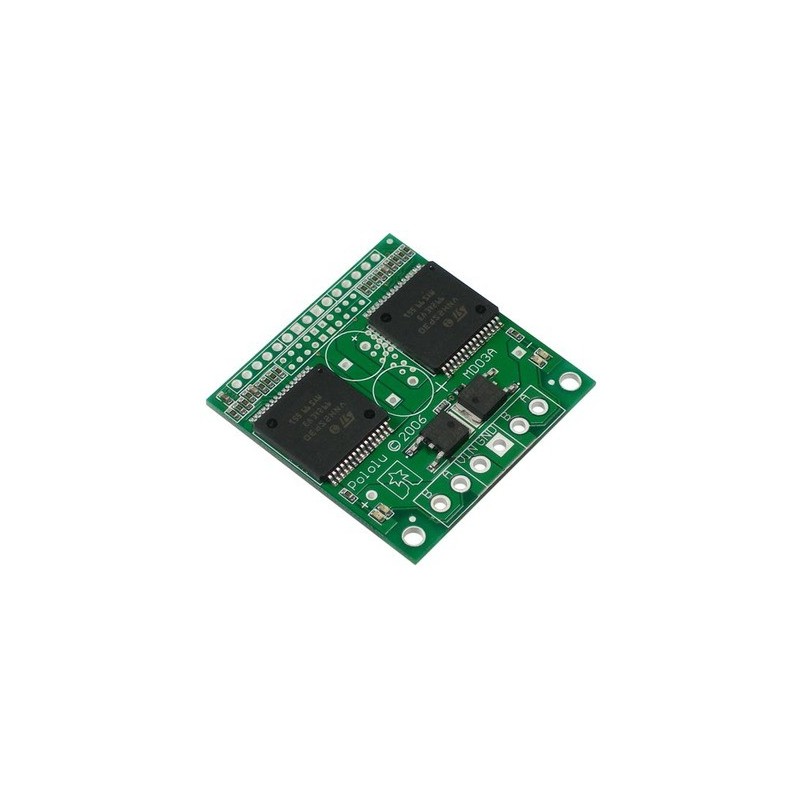

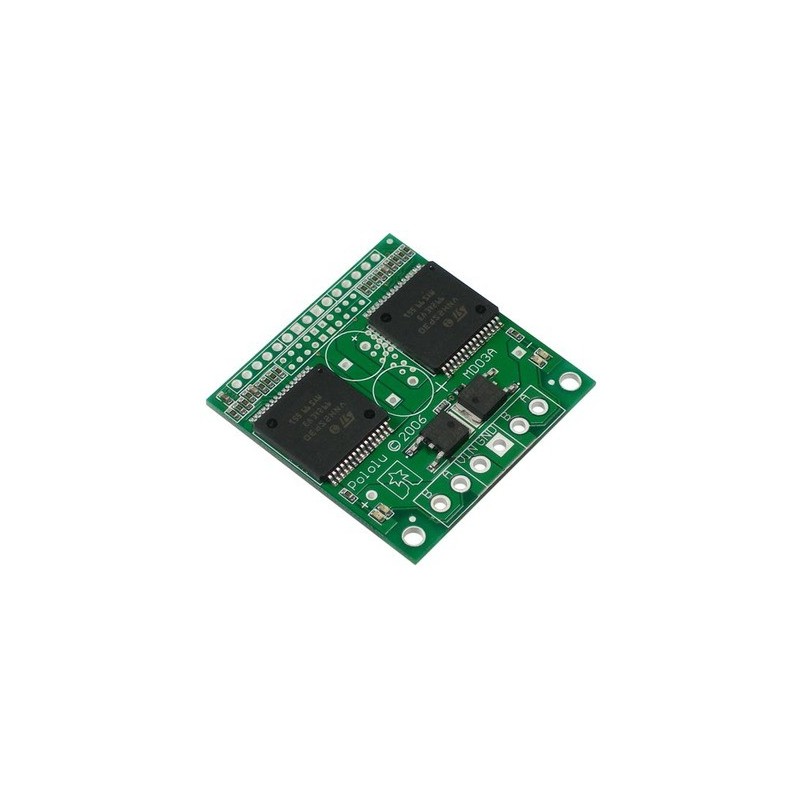

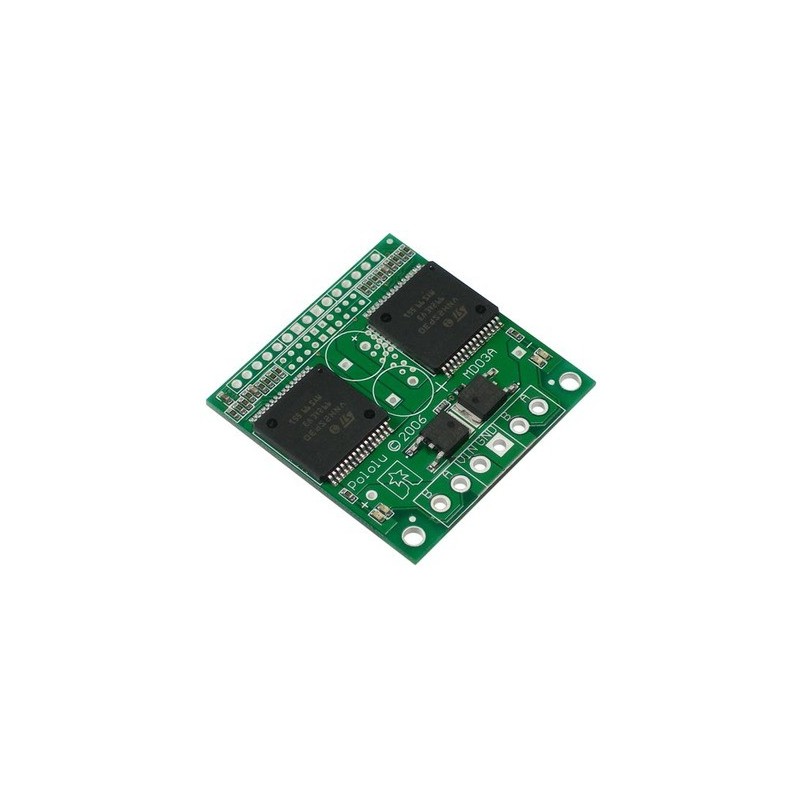

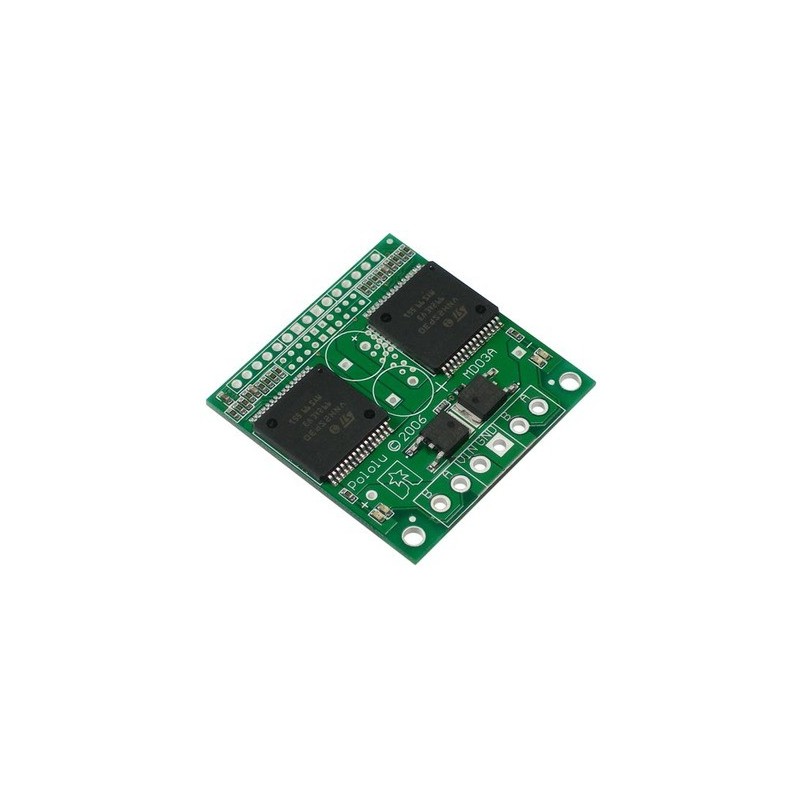

Dual VNH2SP30 Motor Driver Carrier MD03A umożliwia wydajne i bezpieczne sterowanie dwoma silnikami DC w robotach mobilnych oraz układach napędowych. Moduł sprawdza się w projektach wymagających dużej mocy, niezależnej kontroli silników i wysokiej odporności na przeciążenia. Pololu 708

Pololu 708 – Dual VNH2SP30 Motor Driver Carrier MD03A przeznaczony do sterowania dwoma silnikami prądu stałego w projektach robotycznych i mechatronicznych wymagających obsługi podwyższonych prądów. Moduł oparty na dwóch mostkach H VNH2SP30 umożliwia niezależną regulację prędkości i kierunku obrotów każdego silnika, co pozwala na realizację napędu różnicowego w platformach mobilnych.

Sterownik współpracuje z mikrokontrolerami poprzez sygnały logiczne oraz sterowanie PWM, zapewniając płynną regulację pracy silników. Zintegrowane zabezpieczenia chronią układ przed przegrzaniem, przeciążeniem oraz zwarciem, zwiększając niezawodność w zastosowaniach prototypowych i eksploatacyjnych. Konstrukcja nośna ułatwia integrację z systemami zasilania i elementami wykonawczymi w robotach oraz pojazdach autonomicznych.

Cechy

Producent BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Polska sprzedaz@kamami.pl 22 767 36 20

Osoba odpowiedzialna BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Polska sprzedaz@kamami.pl 22 767 36 20

Automotive fully integrated H-bridge motor driver, MultiPowerSO-30, STM, RoHS

Brak towaru

Sterownik silników krokowych, który może pracować z napięciem z zakresu od 20 do 50 V oraz maksymalnym prądem do 4,2 A. Umożliwia konfigurację mikrokroku w zakresie od 2 do 128. DM542

Sterownik silników krokowych, który może pracować z napięciem z zakresu od 20 do 50 V oraz maksymalnym prądem do 5,6 A. Umożliwia konfigurację mikrokroku w zakresie od 2 do 128. DM556

Sterownik silników krokowych, który może pracować z napięciem z zakresu od 24 do 110 VDC lub od 18 do 80 VAC oraz maksymalnym prądem do 7,2 A. Umożliwia konfigurację mikrokroku w zakresie od 2 do 256. DM860H

Moduł z 2-kanałowym sterownikiem silników DC L298P. Płytka została wyposażona w złącze Grove i komunikuje się przez interfejs I2C. Seeed Studio 105020093

Moduł z podwójnym sterownikiem silników DC TB6612FNG. Płytka została wyposażona w złącze Grove i komunikuje się przez interfejs I2C. Seeed Studio 108020103

Moduł z dwoma sterownikami silników DC DRV8830. Płytka została wyposażona w złącze Grove i komunikuje się przez interfejs I2C. Seeed Studio 105020010

Brak towaru

Moduł ze sterownikiem silnika DC DRV8830 o maksymalnym prądzie do 1 A. Płytka została wyposażona w złącze śrubowe i komunikuje się przez interfejs I2C. Pimoroni PIM479

Dwukanałowy sterownik silników DC zasilany napięciem od 2,5 do 12 V o maksymalnym prądzie ciągłym 0,8 A na kanał. Może sterować bipolarnym silnikiem krokowym

Brak towaru

Dwukanałowy sterownik silników prądu stałego (DC) o napięciu pracy od 6 do 30 V i maksymalnym prądzie ciągłym do 20 A. Może być sterowany sygnałem PWM lub za pomocą wbudowanych przycisków. Cytron MDD20A

Shield z dwukanałowym sterownikiem silników DC dla Arduino. Ma napięcie pracy od 7 do 30 V i prąd ciągły do 1,2 A. Może być sterowany sygnałem PWM lub za pomocą wbudowanych przycisków. Cytron SHIELD-3AMOTOR

Jednokanałowy sterownik silnika DC o napięciu pracy od 10 do 45 V i prądzie ciągłym do 40 A. Może być sterowany sygnałem analogowym, PWM, UART, RC lub za pomocą wbudowanych przycisków. Cytron MDS40B

Brak towaru

Dwukanałowy sterownik silników DC o napięciu pracy od 7 do 45 V i prądzie ciągłym do 60 A na kanał. Może być sterowany sygnałem analogowym, PWM, UART, RC lub za pomocą wbudowanych przycisków. Cytron MDDS60

Jednokanałowy sterownik silnika DC o napięciu pracy od 8 do 28 V i prądzie ciągłym do 160 A. Może być sterowany sygnałem analogowym, PWM, UART, RC lub za pomocą wbudowanych przycisków. Cytron MDS160A

Brak towaru

Dwukanałowy sterownik silników prądu stałego (DC) o napięciu pracy od 7 do 30 V i maksymalnym prądzie ciągłym do 10 A. Może być sterowany sygnałem PWM lub za pomocą przycisków. Cytron MDDRC10

Moduł HAT ze sterownikiem silników TB6612FNG oraz sterownikiem PWM PCA9685 przeznaczony do minikomputerów Raspberry Pi. Płytka wyposażona została w złącza śrubowe. Adafruit 4280

Moduł ze sterownikiem silników TB6612FNG oraz sterownikiem PWM PCA9685 dla Raspberry Pi Pico. Pozwala na kontrolowanie ruchu 4 silników DC. Waveshare Pico-Motor-Driver

Dual VNH2SP30 Motor Driver Carrier MD03A umożliwia wydajne i bezpieczne sterowanie dwoma silnikami DC w robotach mobilnych oraz układach napędowych. Moduł sprawdza się w projektach wymagających dużej mocy, niezależnej kontroli silników i wysokiej odporności na przeciążenia. Pololu 708