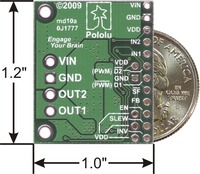

MC33926 Motor Driver Carrier

This breakout board for Freescale’s MC33926 full H-bridge has an operating range of 5 – 28 V and can deliver almost 3 A continuously (5 A peak) to a DC motor. The MC33926 works with 3 – 5 V logic levels, supports ultrasonic (up to 20 kHz) PWM, and features current feedback, under-voltage protection, over-current protection, and over-temperature protection.

|

The MC33926 motor driver carrier can supply up to almost 3 A continuous current to a single brushed DC motor at 5 – 28 V, and it can tolerate peak currents up to 5 A for a few seconds, making this a great general-purpose motor driver for medium-sized DC motors. The MC33926 supports ultrasonic (up to 20 kHz) pulse width modulation (PWM) of the motor output voltage, which eliminates the audible switching sounds caused by PWM speed control, and a current feedback circuit outputs an analog voltage on the FB pin that is proportional to the output current. Since this board is a carrier for the Freescale Semiconductor MC33926 H-bridge, we recommend careful reading of the MC33926 datasheet (1MB pdf).

If you have two motors to control, please consider the Dual MC33926 motor driver carrier.

|

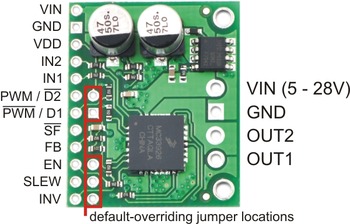

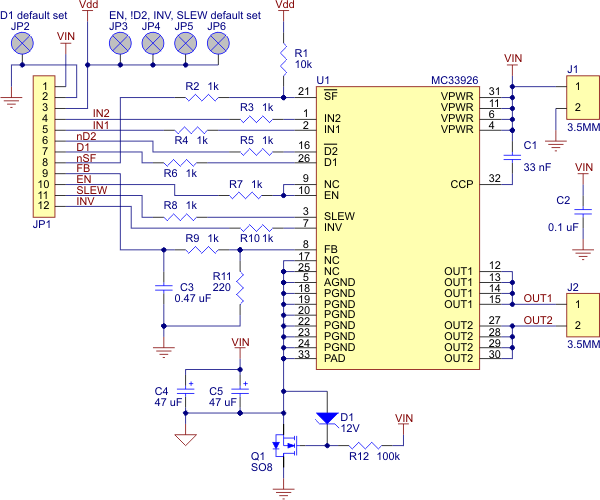

The default states of many of the MC33926 logic input pins requires that many external connections be made to use this motor driver. To reduce the number of necessary external connections, the board has five default-overriding jumpers. All of the default-overriding jumpers are tied to VDD, except the D1 jumper, which is tied to GND. All VDD jumper pads are circles; the ground jumper pad is square.

| PIN | Default State | Description |

|---|---|---|

| VIN | HIGH | This is the main 5 – 28 V motor power supply connection, which should typically be made to the larger VIN pad. Operation from 5 – 8 V reduces maximum current output; the device is also protected for transients up to 40 V. The smaller VIN pad can be used to distribute the VIN node to the rest of the application circuit; for lower-current applications, the pin can also be used to power the motor driver and motor. |

| GND | LOW | Ground connection for logic and motor power supplies. |

| OUT2 | HIGH | The motor output pin controlled by IN2. |

| OUT1 | HIGH | The motor output pin controlled by IN1. |

| VDD | HIGH | 3-5 V logic supply connection. This pin is used only for the SF pull-up and default-overriding jumpers; in the rare case where none of those features is used, VDD can be left disconnected. |

| IN2 | HIGH | The logic input control of OUT2. PWM can be applied to this pin (typically done with both disable lines inactive). |

| IN1 | HIGH | The logic input control of OUT1. PWM can be applied to this pin (typically done with both disable lines inactive). |

| PWM / D2 | LOW | Inverted disable input: when D2 is low, OUT1 and OUT2 are set to high impedance. A D2 PWM duty cycle of 70% gives a motor duty cycle of 70%. Typically, only one of the two disable pins is used, but the default is for both disable pins to be active. |

| PWM / D1 | HIGH | Disable input: when D1 is high, OUT1 and OUT2 are set to high impedance. A D1 PWM duty cycle of 70% gives a motor duty cycle of 30%. Typically, only one of the two disable pins is used, but the default is for both disable pins to be active. |

| SF | HIGH | Status flag output: an over-current (short circuit) or over-temperature event will cause SF to be latched LOW. If either of the disable pins (D1 or D2) are disabling the outputs, SF will also be LOW. Otherwise, this pin is weakly pulled high. This allows the SF pins of multiple units to connected to a single input. |

| FB | LOW | The FB output provides analog current-sense feedback of approximately 525 mV per amp. |

| EN | LOW | Enable input: when EN is LOW, the chip is in a low-current sleep mode. |

| SLEW | LOW | Output slew rate selection input. A logical LOW results in a slow output rise time (1.5 ěs – 6 ěs). A logical HIGH selects a fast output rise time (0.2 ěs – 1.45 ěs). This pin should be set HIGH for high-frequency (over 10 kHz) PWM. |

| INV | LOW | A logical high value inverts the meaning of IN1 and IN2. This allows INV to function as a direction line if IN1 and IN2 are set to different values. |

In a typical application, five I/O lines are used to connect the motor driver to a microcontroller: the two input lines, IN1 and IN2, for direction control, one of the disable lines, D1 or D2, for PWM speed control, the status flag, SF, for monitoring motor driver errors, and the current sense output, FB, for monitoring motor current draw (connected to an analog-to-digital converter input). The control lines can be reduced to two pins if PWM signals are applied directly to the two input pins with both disable pins held inactive. A two-pin interface can also be achieved using one of the disable lines for PWM speed control and the INV input for direction control with IN1 and IN2 held at different values (i.e. one set HIGH and the other set LOW). In each of these cases, the other unused lines must be set to enable proper operation. For example, if D2 is used for the PWM input (as is typically the case), D1 must be held low to prevent it from disabling the motor driver. The circuit board provides convenient jumper points for overriding the motor driver defaults without having to connect extra wires to the module.

The current sense and status flag connections are optional, though monitoring of the status flag can allow detection of latched fault conditions. The status flag is an open-drain output, so multiple units can have their status flag pins wired together for applications where I/O pins are scarce and determining which motor driver is experiencing a fault condition is not necessary.

Note that the default state of the enable pin, EN, is LOW, which holds the chip in a low-current sleep mode. You will need to hold this pin high (either with an external connection or via the default-overriding jumper next to the pin) to allow the chip to run.

The MC33926 has under-voltage, over-current, and over-temperature protection. Some protection events are indicated by the status flag pin (SF), which is an active-low pin allowing the SF pin from multiple boards to connected to a single input. If the chip detects an over-current or over-termperature event, the SF is latched LOW and OUT1 and OUT2 are set to high-impedance. To unlatch the status flag pin toggle the D1, D2 , EN or VIN lines. The carrier board has a reverse-protection MOSFET for added protection to the motor driver chip.

The MC33926 motor driver used on the carrier board has a maximum current rating of 5 A continuous. However, the chip by itself will overheat at lower currents. For example, in our tests at room temperature with no forced air flow, the chip was able to deliver 5 A for 5 s and 4 A for 18 s before the chip’s thermal protection started reducing the current. A continuous current of 3 A was right at the over-temperature threshold; in some tests the thermal protection kicked in after a minute, and in other tests the chip delivered 3 A for over five minutes without triggering thermal protection. The actual current you can deliver will depend on how well you can keep the motor driver cool. The carrier’s printed circuit board is designed to draw heat out of the motor driver chip, but performance can be improved by adding a heat sink. Our tests were conducted at 100% duty cycle; PWMing the motor will introduce additional heating proportional to the frequency.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

Unlike other H-Bridges, the 33926 has a feature that allows it to gracefully reduce current as the current exceeds 5 A or as the chip temperature approaches its limit. This means that if you push the chip close to its limit, you will see less power to the motor, but it might allow you to avoid a complete shutdown.

|

|

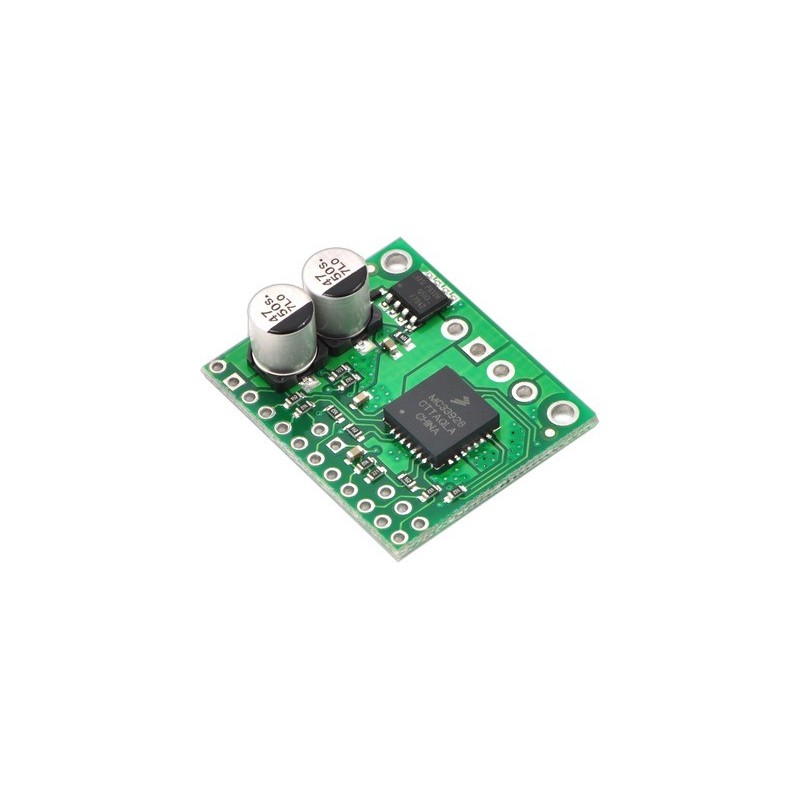

A 20-pin straight breakaway male header is included with the MC33926 carrier board, which can be used to connect the PCB to perfboards or breadboards. The board also includes two 2-pin 3.5mm terminal blocks for making simple motor connections.

|

|

75:1 Metal Gearmotor 25Dx54L mm with 48 CPR Encoder |

|

Dual MC33926 Motor Driver Carrier |

|

TB6612FNG Dual Motor Driver Carrier |

Cechy

Producent BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Polska sprzedaz@kamami.pl 22 767 36 20

Osoba odpowiedzialna BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Polska sprzedaz@kamami.pl 22 767 36 20

X-NUCLEO-IHM02A1 to moduł sterownika dwóch silników krokowych oparty na dwóch układach L6470. Poziom logiczny 3,3 lub 5 V, sterowanie przez SPI. Złącza zgodne z Arduino i STM32 Nucleo

Nakładka przeznaczona do użycia z płytkimi z serii Feather zawiera dwa układy TB6612 pozwalające na sterowanie silnikami prądu stałego lub silnikami krokowymi. Do komunikacji z nakładką wykorzystywany jest interfejs I2C. Adafruit 2927

Pololu G2 24v13 High Power to miniaturowy sterownik silnika DC. Zasilanie sterownika: 6,5 - 40 V. Wydajność prądowa modułu: 13 A. Moduł posiada zabezpieczenie przed napięciem wstecznym i przepięciami. Pololu 2992

Brak towaru

Pololu G2 18v17 to miniaturowy sterownik silnika DC. Zasilanie sterownika: 6,5 - 30 V. Wydajność prądowa modułu: 17 A.

Moduł posiada zabezpieczenie przed napięciem wstecznym i przepięciami. Pololu 2991

Brak towaru

Moduł pozwala połączyć zalety Raspberry Pi i Arduino, wyposażony jest w mikrokontroler ATmega32u4 z botloaderem zgodnym z Arduino i podwójny sterownik silników. Pololu 3119

Moduł pozwala połączyć zalety Raspberry Pi i Arduino, wyposażony jest w mikrokontroler ATmega32u4 z botloaderem zgodnym z Arduino i podwójny sterownik silników. Pololu 3118

Moduł rozszerzeń (shield) ze sterownikiem silnika krokowego dla Arduino. Pozwala na sterowanie napędami pracującymi z napięciem do 40 V i poborem prądu do 2 A na cewkę. DFRobot DRI0035

Brak towaru

DRV8825 Stepper Motor Driver Carrier to sterownik silnika krokowego z układem DRV8825, pozwala na zasilanie silnika bipolarnego prądem do 1,5A na fazę, bez użycia radiatora. Układ może być zasilany napięciem do 45V, w zestawie znajduje się radiator. Jest kompatybilny z Pololu 2133

Brak towaru

Sterownik silnika krokowego z układem Allegro A4988 (A4988 Stepper Motor Driver Carrier) pozwala na zasilanie silnika bipolarnego prądem do 2A na fazę. Układ może być zasilany napięciem do 35V, w zestawie znajduje się radiator. Jest kompatybilny z Pololu 1182

Sterownik silnika krokowego, napięcie zasilania cewek silnika 6..30 V, napięcie pracy logiki sterownika 0..5 V lub 0..3,3 V. Możliwa regulacja prądu sterowania na fazę obrotu podczas pracy sterownika. ROB-12779

Brak towaru

Pololu G2 18v25 to miniaturowy sterownik silnika DC. Zasilanie sterownika: 6.5V...30V. Wydajność prądowa modułu: 25A.

Moduł posiada zabezpieczenie przed napięciem wstecznym i przepięciami. Pololu 2994

Brak towaru

Pololu G2 24v21 to miniaturowy sterownik silnika DC. Zasilanie sterownika: 6.5V...40V. Wydajność prądowa modułu: 21A.

Moduł posiada zabezpieczenie przed napięciem wstecznym i przepięciami. Pololu 2995

Sterownik silnika krokowego A4988 operujący na napięciach 8..35 V i prądzie 1,2 A. Pololu 2128

Rozszerzenie dla Raspberry Pi z dwoma sterownikami silników obsługującymi zakres napięć 5-28 V i prąd ciągły 3 A (chwilowy 5 A) każdy. Pololu 2755

Brak towaru

Sterownik silnika krokowego AMIS-30543 operujący w zakresie napięć 6..30 V i prądzie 1,8 A. Pololu 2970

Niewielka płytka z sterownikiem silnika szczotkowego MAX14870 działającym w napięciach od 4,5V do 36V i prądzie ciągłym 1,7 A (2,5 A chwilowym). Pololu 2961

MC33926 Motor Driver Carrier