- Out-of-Stock

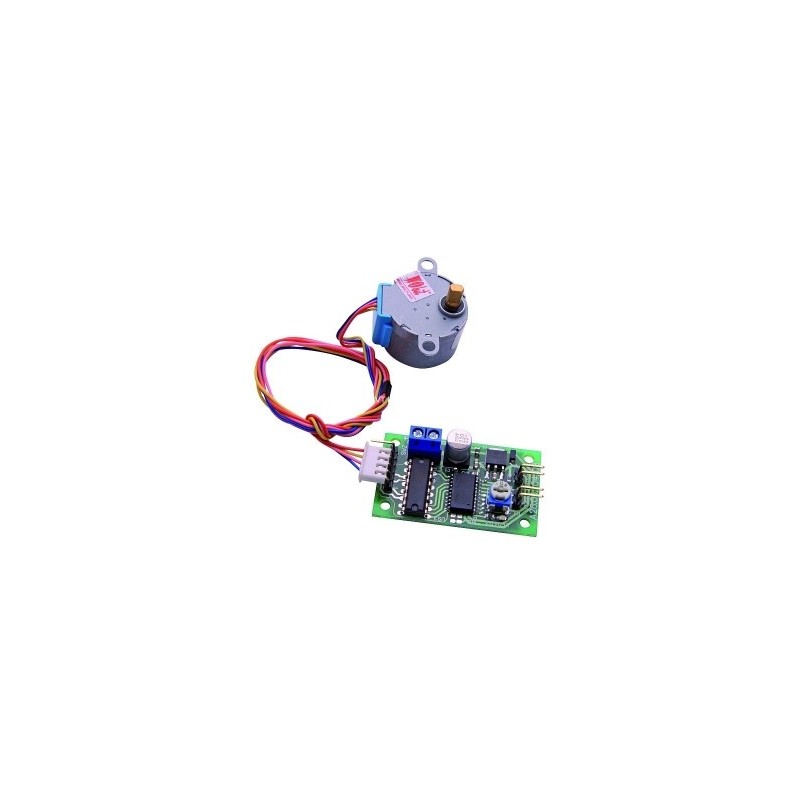

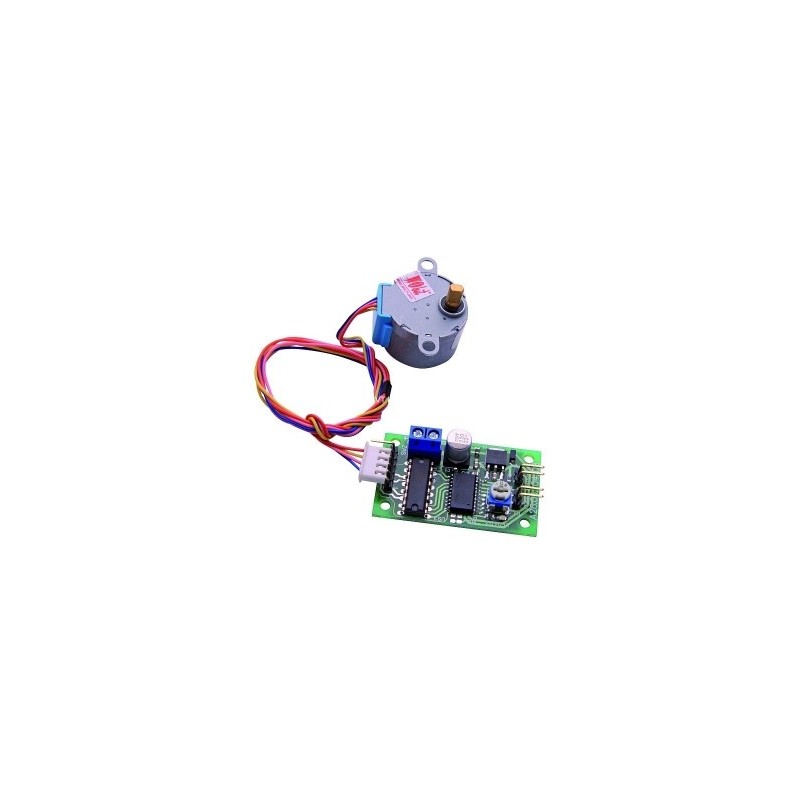

The presented layout, in addition to its simple design and small dimensions, has some additional settings that we will not meet in an ordinary controller. Step work is the simplest way to control a stepper motor. Half-step operation is the addition of intermediate states in the control sequence. In practice, it causes more smooth operation of the motor, but increases the power consumption. And finally, the choice of the stopping method: static or dynamic. "Dynamic", ie: on the output of the controller, the combination of supply signals is maintained from the moment of providing the stop signal, ie the appropriate voltage supplying the motor coils is switched on. In practice, this causes it to lock in a specific position, but current flows through the motor windings, which is the reason for their heating up. Static stop causes disconnection of the motor supply in the stopped state. Thus, its axis rotates freely, and the system takes only a small quiescent current.

The device is particularly recommended in automation systems - everywhere where there are stepper motors

Selected parameters:

The set includes a printed circuit board, a programmed layout, a set of elements (without a stepper motor) and documentation

A detailed description in EP 8/10

Note: The stepper motor can be purchased separately. Code

Download

Manufacturer AVT SPV Sp. z o.o. Leszczynowa 11 03-197 Warszawa Poland zamowienia@avt.pl

Responsible person AVT SPV Sp. z o.o. Leszczynowa 11 03-197 Warszawa Poland zamowienia@avt.pl

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!

No product available!