zł365.91 tax excl.

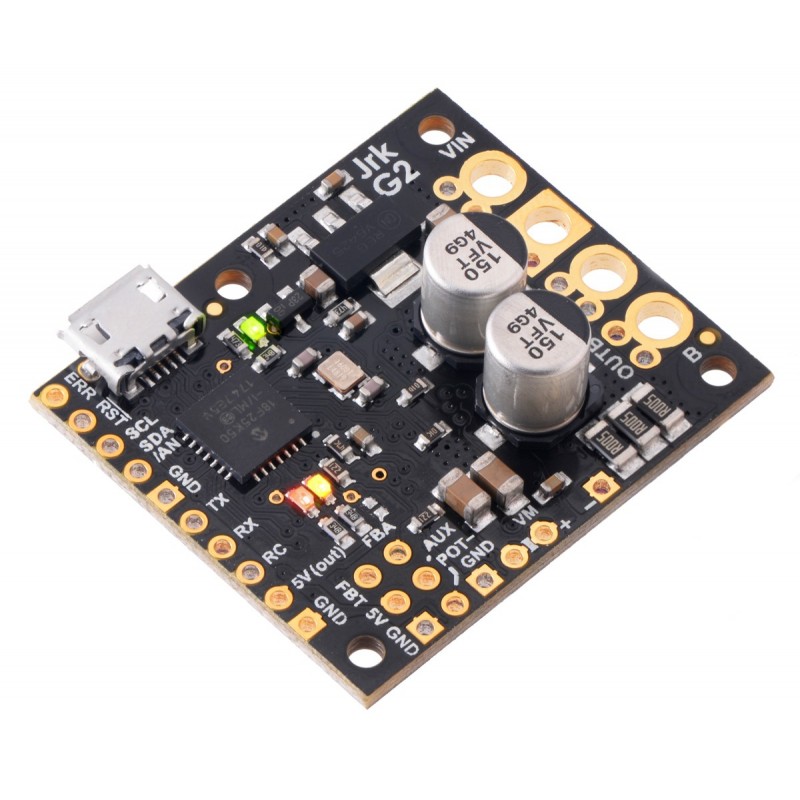

This powerful motor controller makes closed-loop speed or position (but not both!) control of a brushed DC motor easy, with quick configuration over USB using our free software. It supports five control interfaces: USB, TTL serial, I²C, analog voltage (potentiometer), and hobby radio control (RC).

This version offers a wide 6.5 V to 30 V operating range and can deliver continuous output currents up to 19 A without a heat sink.

With integrated support for analog voltage or tachometer (frequency) feedback, the second-generation G2 family of Jrk motor controllers makes it easy to add closed-loop control of speed or position (but not both!) of a single brushed DC motor to a variety of projects. These versatile, general-purpose modules support five different control interfaces: USB for direct connection to a computer, TTL serial and I²C for use with a microcontroller, RC hobby servo pulses for use in an RC system, and analog voltages for use with a potentiometer or analog joystick. They also offer many settings that can be configured using our free configuration software utility for Windows, Linux, and macOS. This software simplifies initial setup of the device and allows for in-system testing and monitoring of the controller via USB (a micro-B USB cable is required to connect the Jrk G2 to a computer).

The table below lists the members of the Jrk family, including the original versions, and shows the key differences among them.

| Jrk 21v3 | Jrk 12v12 | Jrk G2 21v3 | Jrk G2 18v19 | Jrk G2 24v13 | Jrk G2 18v27 | Jrk G2 24v21 | |

|---|---|---|---|---|---|---|---|

| Recommended max operating voltage: |

28 V(1) | 16 V | 28 V(1) | 24 V(2) | 34 V(3) | 24 V(2) | 34 V(3) |

| Max nominal battery voltage: |

24 V | 12 V | 24 V | 18 V | 28 V | 18 V | 28 V |

| Max continuous current (no additional cooling): |

2.5 A* | 12 A | 2.6 A | 19 A | 13 A | 27 A | 21 A |

| USB, TTL serial, Analog, RC control: |

|

|

|

|

|

|

|

| I²C control: |  |

|

|

|

|

||

| Hardware current limiting: |  |

|

|

|

|||

| Dimensions: | 1.35″ × 1.35″ | 1.85″ × 1.35″ | 1.0″ × 1.2″ | 1.4″ × 1.2″ | 1.7″ × 1.2″ | ||

| 1 Transient operation (< 500 ms) up to 40 V. 2 30 V absolute max. 3 40 V absolute max. * Reduced from “3 A” based on newer, more stringent tests. The value now is directly comparable to the rating for the newer G2 21v3. |

|||||||

The Jrk G2 18v19 operates from 6.5 V to 30 V and can deliver a continuous output current of 19 A without a heat sink. Note that 30 V is the absolute maximum for this controller; the maximum recommended operating voltage is 24 V, and the maximum recommended nominal battery voltage is 18 V. For applications using higher voltages (such as 24 V batteries), we recommend the higher-voltage Jrk G2 24v13 or Jrk G2 24v21.

If you need to identify which version you have, you can just plug it into a computer through USB and the Jrk software will tell you. For quick visual identification without a computer, you can distinguish this version from the identically sized Jrk G2 24v13 by the number 150 on top of the tall silver electrolytic capacitors.

Pieces from the 0.1″ header strip can be soldered into the small holes on the logic connection side of the board to enable use with solderless breadboards, perfboards, or 0.1″ connectors, or you can solder wires directly to these holes for the most compact installation.The Jrk ships with a 0.1″ breakaway male header strip and two 2-pin 5mm terminal blocks. You can solder the terminal blocks to the four large through-holes to make your motor and motor power connections (see our short video on terminal block installation), or you can solder an 8-pin piece of the 0.1″ header strip into the smaller through-holes that border these larger holes. Note, however, that the terminal blocks are only rated for 16 A, and each header pin pair is only rated for a combined 6 A, so for higher-power applications, thick wires should be soldered directly to the board.

Note: A USB A to micro-B cable (not included) is required to connect the Jrk G2 to a computer for initial configuration.

The Jrk G2 family features a number of improvements compared to our original two Jrk motor controllers (21v3 and 12v12). Most importantly, the Jrk G2 controllers support both higher operating voltages and larger output currents while being even more compact than their predecessors. Other new features include:

The Jrk G2 controllers are not drop-in replacements for the original Jrk controllers because of differences in their form factors and pin arrangements, although wiring changes should be straightforward. The Jrk G2 serial protocol is compatible with (and generally a superset of) the original Jrk serial protocol, so in many cases, serial interface software running on a microcontroller or computer will not need to be modified to work with a Jrk G2.

| Motor channels: | 1 |

|---|---|

| Control interface: | USB; non-inverted TTL serial; I²C; RC servo pulses; analog voltage |

| Minimum operating voltage: | 6.5 V |

| Maximum operating voltage: | 30 V2 |

| Continuous output current per channel: | 19 A3 |

| Maximum PWM frequency: | 20 kHz |

| Reverse voltage protection?: | Y |

| Version: | G2 18v19 (30 V max, 19 A max continuous) |

| Connectors soldered?: | N |

| Size: | 1.2″ × 1.4″ × 0.42″1 |

|---|---|

| Weight: | 6.5 g1 |

Data sheet

Manufacturer BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Responsible person BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

DC motor driver with voltage 6.5..40V and maximum continuous current 21A. It has the ability to easily implement the feedback loop and numerous control interfaces. Polol 3149

No product available!

DC motor driver with voltage 4.5..28V and maximum continuous current of 2.6A. It has the ability to easily implement the feedback loop and numerous control interfaces. Polol 3143

No product available!

DC motor driver with voltage 4.5..28V and maximum continuous current of 2.6A. It has the ability to easily implement the feedback loop and numerous control interfaces. Polol 3142

No product available!

ESC type controller for a DC motor with a supply voltage of 3.7 V to 5 V. It offers a maximum output current of up to 1.5 A and allows you to control two motors independently

No product available!

Miniature ESC type controller for a DC motor with an input from 3.7 V to 5 V. Offers an additional output current of up to 1.5 A and allows you to control the motor in a channel mixing device

2-channel brush motor controller module with PWM signal mixing function. It allows you to control two DC motors with a current consumption of up to 5 A per channel

3-channel brush motor controller module with PWM signal mixing function. It allows you to control three DC motors with a current consumption of up to 15 A per channel

3-channel brush motor controller module with PWM signal mixing function. It allows you to control three DC motors with a current consumption of up to 3 A per channel

The UX-52 panel brush motor speed controller is a versatile device with speed adjustment from 90 to 1400 rpm. It offers precise control of motors with an input voltage of 220VAC, featuring a solid construction and a convenient digital display.

KAmod Motor Driver is an advanced DC motor controller powered by 6-30 V, enabling power regulation using the PWM method and control of the direction of rotation, compatible with analog and PWM signals from various sources, equipped with overload and thermal protections and soft start and stop functions

The dual-channel KAmod Motor Driver TB6612FNG with MOSFET H-bridges enables precise control of DC and stepper motors with PWM frequency up to 100 kHz. The compact design, wide voltage range, and protections make the module suitable for mobile projects, robotics, and automation.

This L298N module allows independent control of two DC motors or one stepper motor, ideal for robotics and DIY projects. It supports power supplies from 7V to 35V and has a built-in 5V regulator that can power additional circuits. Control is performed via the ENA, ENB, and IN1–IN4 pins, allowing for adjustable rotational direction and speed. The module is equipped with protection diodes and filter capacitors for stable and reliable operation.

No product available!

An H-bridge capable of controlling one DC motor in both directions or two unidirectional motors at voltages from 4.5 to 44 V and continuous current up to 1.1 A. The module offers three operating modes (PH/EN, IN/IN, half-bridge), built-in current limiting and measurement, and protection against overheating, overload, undervoltage, and reverse polarity. Its compact design, flexible logic power supply (1.8–5.5 V), and simple control make it ideal for robotics, automation, and hobby projects. Pololu 4972

An H-bridge capable of controlling one DC motor in both directions or two unidirectional motors at voltages from 4.5 to 44 V and continuous currents up to 1.3 A. The module offers three operating modes (PH/EN, IN/IN, half-bridge), built-in current limiting and measurement, and protection against overheating, overload, undervoltage, and reverse polarity. Its compact design, flexible logic power supply (1.8–5.5 V), and simple control make it ideal for robotics, automation, and hobby projects. Pololu 4971

This board allows for simultaneous control of two motors with full direction and stopping control, ideal for robotic buggies and educational vehicles. It features built-in short circuit, overload, and overheat protection, as well as a stabilized 3V output to power the micro:bit. The Edge Connector and additional pins allow for easy connection of sensors, switches, and accessories, expanding the project\'s functionality. Programming is supported by dedicated MakeCode blocks and support for the Kitronik 5698 Python.

An H-bridge driver that provides bidirectional control of a high-power DC motor with a voltage range of 5-60 V and a continuous current of up to 11 A. The module supports PWM signals up to 100 kHz, features a current measurement (CS) output based on the ACS711 sensor, and features reverse polarity and short-circuit protection. It is compatible with both 3.3 V and 5 V logic, enabling easy integration with popular microcontroller platforms. Ideal for robotics, automation, and DIY projects requiring high performance and reliability. Pololu 2993

FeatherWing expansion board for controlling DC motors, stepper motors, and servo motors, based on the PCA9685 PWM controller and TB6612FNG H-bridge drivers. Adafruit 3243

A compact motor controller designed for the Pimoroni Yukon platform, capable of driving two DC motors or one bipolar stepper motor. The DRV8424P chip provides stable control with a supply voltage of 5 to 17 V and a current of up to 1.6 A continuous per channel. The module offers adjustable current limiting, thermal protection, and error detection. Pimoroni PIM693

No product available!

A powerful controller designed to drive a single brushed DC motor with an encoder in the Pimoroni Yukon system. It offers up to 8 A continuous and 12 A peak current at a supply voltage of 5 to 17 V, making it suitable for demanding robotic projects. The module provides precise control thanks to encoder support and built-in current, temperature, and error sensors. Pimoroni PIM691

No product available!

This powerful motor controller makes closed-loop speed or position (but not both!) control of a brushed DC motor easy, with quick configuration over USB using our free software. It supports five control interfaces: USB, TTL serial, I²C, analog voltage (potentiometer), and hobby radio control (RC).