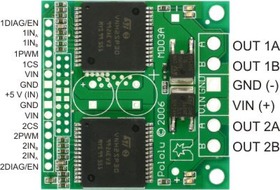

Dual VNH3SP30 Motor Driver Carrier MD03A

If you are looking to drive two high-power motors through one compact unit, these dual VNH3SP30 motor driver carriers are perfect for you. With these boards, it’s easy to get a medium-sized, differential drive robot running in no time. The VNH3 version is a lower-cost option than its VNH2 counterpart.

|

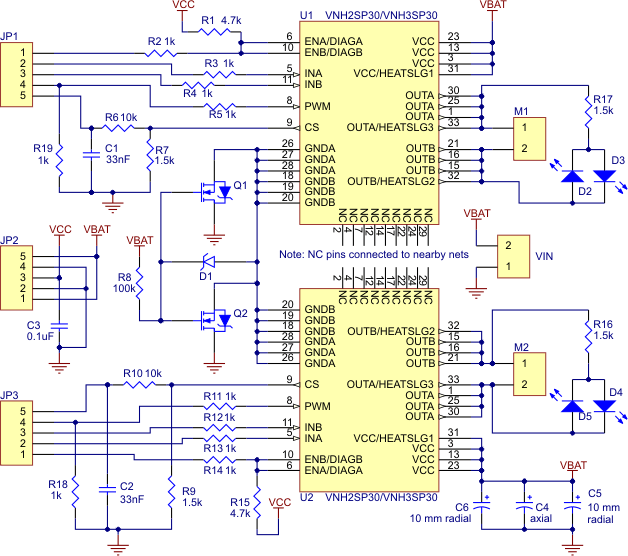

The Pololu dual high-power motor drivers are compact carriers for the VNH3SP30 and VNH2SP30 motor driver integrated circuits from ST. The board incorporates most of the components of the typical application diagram on page 8 of the VNH2SP30 datasheet, including pull-up and current-limiting resistors and a FET for reverse battery protection. (The current sense circuit is populated on both versions of the board, but only the VNH2SP30 supports current sense.) To keep the number of I/O lines down, the two enable/diagnostic lines on each chip are tied together. All you need to add is a microcontroller or other control circuit to turn the H-Bridges on and off.

Please note that we offer several other products based on these same chips, including single carrier boards for controlling one motor, the qik 2s12v10 dual serial motor controller, the TReX motor controller, the jrk 12v12 USB motor controller with feedback, and the Orangutan X2 robot controller. We also have a family of higher-power motor drivers that can deliver more current over a wider operating voltage range.

|

In a typical application, the power connections are made on one end of the board, and the control connections are made on the other end. +5 volts must be supplied to the board through the smaller 0.1"-spaced pins; the input voltage is available at those pins as well, but the connection is not intended for currents exceeding a few amps. The diagnostic pins can be left disconnected if you do not want to monitor the fault conditions of the motor drivers. INA and INB control the direction of each motor, and the PWM pins turns the motors on or off. For the VNH2SP30 version, the current sense (CS) pins will output approximately 0.13 volts per amp of output current. If you want to add current sensing to the VNH3SP30 version, or if you want higher-accuracy current sensing with the VNH2SP30 version, please consider our ±30A ACS714 current sensor carrier.

|

The dual motor driver PCB includes provisions for installing up to three large capacitors to limit disturbances on the main power line. Two 10mm radial capacitors may be mounted between the motor driver ICs, and an axial capacitor may be mounted between the ICs and power connections. It is generally not necessary to use all three capacitors; two radial capacitors are included with each unit. For applications that require a low profile, a single capacitor can be installed on its side as shown in the picture to the right.

Note: A 15-pin male header, three 2-pin terminal blocks, and two electrolytic capacitors are included but not soldered onto the boards. No printed documentation is shipped with these items; please see the VNH3SP30 and VNH2SP30 datasheets linked under the Resources tab.

| VNH3SP30 | VNH2SP30 | |

|---|---|---|

| Operating supply voltage (Vcc) | 5.5 – 36 V* | 5.5 – 16 V |

| Maximum current rating | 30 A | 30 A |

| MOSFET on-resistance (per leg) | 34 mΩ | 19 mΩ |

| Maximum PWM frequency | 10 kHz | 20 kHz |

| Current sense | none | approximately 0.13 V/A |

| Over-voltage shutoff | 36 V* | 16 V minimum (19 V typical) |

| Time to overheat at 20 A** | 8 seconds | 35 seconds |

| Time to overheat at 15 A** | 30 seconds | 150 seconds |

| Current for infinite run time** | 9 A | 14 A |

*Manufacturer specification. In our experience, shoot-through currents make PWM operation impractical above 16 V.

**Typical results using Pololu motor driver carrier with 100% duty cycle at room temperature.

The motor drivers have maximum current ratings of 30 A continuous. However, the chips by themselves will overheat at lower currents (see table above for typical values). The actual current you can deliver will depend on how well you can keep the motor drivers cool. The carrier printed circuit board is designed to draw heat out of the motor driver chips, but performance can be improved by adding a heat sink. In our tests, we were able to deliver short durations (on the order of milliseconds) of 30 A and several seconds of 20 A without overheating. At 6 A, the chip gets just barely noticeably warm to the touch. For high-current installations, the motor and power supply wires should also be soldered directly instead of going through the supplied terminal blocks, which are rated for up to 15 A.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

Many motor controllers or speed controllers can have peak current ratings that are substantially higher than the continuous current rating; this is not the case with these motor drivers, which have a 30 A continuous rating and over-current protection that can kick in as low as 30 A (45 A typical). Therefore, the stall current of your motor should not be more than 30 A. (Even if you expect to run at a much lower average current, the motor can still draw high currents when it is starting or if you use low duty cycle PWM to keep the average current down.)

|

| Schematic of the Pololu Dual High Current Motor Driver Carrier |

|---|

|

Sharp GP2Y0A21YK0F Analog Distance Sensor 10-80cm |

|

Pololu Universal Aluminum Mounting Hub for 6mm Shaft Pair, 4-40 Holes |

|

Pololu 37D mm Metal Gearmotor Bracket Pair |

Data sheet

Manufacturer BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Responsible person BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

KAmod Motor Driver is an advanced DC motor controller powered by 6-30 V, enabling power regulation using the PWM method and control of the direction of rotation, compatible with analog and PWM signals from various sources, equipped with overload and thermal protections and soft start and stop functions

A single-channel DC motor driver with an I2C interface. It is powered from 4.5 V to 48 V and can deliver up to 2.2 A of current. A board with soldered connectors. Pololu 5060

No product available!

A single-channel DC motor driver with an I2C interface. It is powered from 4.5 V to 48 V and can deliver up to 2.2 A of current. A board with connectors for mounting. Pololu 5061

No product available!

A single-channel DC motor controller with a UART TTL interface. It is powered from 4.5 V to 48 V and can deliver up to 2.2 A of current. Board with soldered connectors. Pololu 5062

No product available!

A single-channel DC motor controller with a UART TTL interface. It is powered from 4.5 V to 48 V and can deliver up to 2.2 A of current. Board with connectors for assembly. Pololu 5063

No product available!

Advanced, compact stepper motor driver with TMC2209 chip that offers smooth, quiet operation, high performance, various operating modes and easy configuration, ideal for 3D printers and other applications. modTMC2209v4

No product available!

A stepper motor controller that can operate with a voltage range of 24 to 110 VDC or 18 to 80 VAC and a maximum current of up to 8.4 A. It allows micro step configuration in the range of 2 to 256. 2DM860H

A stepper motor controller that can operate with a voltage range of 24 to 110 VDC or 18 to 80 VAC and a maximum current of up to 8.4 A. It allows micro step configuration in the range of 2 to 256. 2DM860H

A compact stepper motor controller with the TMC2209 system with an operating voltage from 4.75 to 28 V. It offers smooth, quiet operation, high efficiency, various operating modes and easy configuration. It is controlled via the STEP/DIR interface and is an ideal solution for 3D printers and similar applications. BIGTREETECH TMC2209 V1.3

No product available!

Compact stepper motor controller with the TMC2208 system with an operating voltage from 4.75 to 36 V. It offers smooth, quiet operation, high efficiency, various operating modes and easy configuration. It is controlled via the STEP/DIR interface and is an ideal solution for 3D printers and similar applications. BIGTREETECH TMC2208 V3.0

No product available!

Compact stepper motor controller with the TMC2130 system with operating voltage from 5.5 to 45 V. It offers smooth, quiet operation, high efficiency, various operating modes and easy configuration. It is controlled via the STEP/DIR interface and is an ideal solution for 3D printers and similar applications. BIGTREETECH TMC2130 V3.0

A compact stepper motor controller with a TMC2225 system with an operating voltage from 4.75 to 36 V. It offers smooth, quiet operation, high efficiency, various operating modes and easy configuration. It is controlled via the STEP/DIR interface and is an ideal solution for 3D printers and similar applications. BIGTREETECH TMC2225 V1.0

Compact stepper motor controller with the TMC2226 system with an operating voltage from 4.75 to 29 V. It offers smooth, quiet operation, high efficiency, various operating modes and easy configuration. It is controlled via the STEP/DIR interface and is an ideal solution for 3D printers and similar applications. BIGTREETECH TMC2226 V1.0

No product available!

Compact stepper motor controller with the TMC5160 system with operating voltage from 8 to 35 V. It offers smooth, quiet operation, high efficiency, various operating modes and easy configuration. It is controlled via the SPI interface and is an ideal solution for 3D printers and similar applications. BIGTREETECH TMC5160 V1.3

A two-channel DC motor controller with a UART TTL interface. It is powered from 1.8 V to 22 V and can deliver up to 1.6 A per motor. Board with connectors for assembly. Pololu 5081

A two-channel DC motor controller with a UART TTL interface. It is powered from 1.8 V to 22 V and can deliver up to 1.6 A per motor. Board with connectors. Pololu 5080

A two-channel DC motor controller with a I2C interface. It is powered from 1.8 V to 22 V and can deliver up to 1.6 A per motor. Board with connectors for assembly. Pololu 5079

Dual VNH3SP30 Motor Driver Carrier MD03A