zł34.52 tax excl.

This compact breakout board for Maxim’s MAX14870 motor driver offers a wide operating voltage range of 4.5 V to 36 V and can deliver a continuous 1.7 A (2.5 A peak) to a single brushed DC motor. It features a simple two-pin speed/direction interface and built-in protection against reverse-voltage, under-voltage, over-current, and over-temperature.

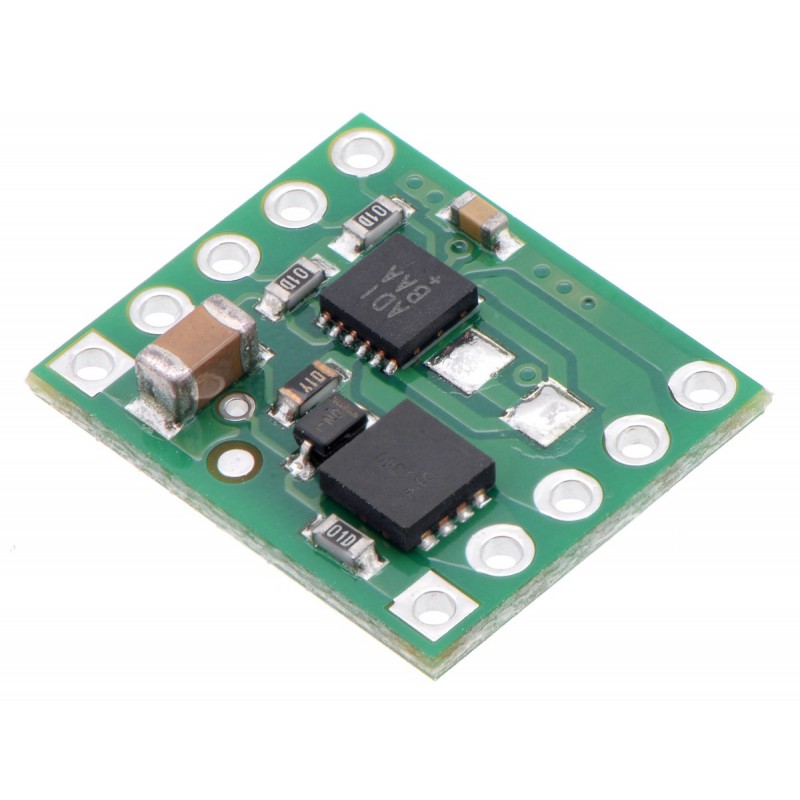

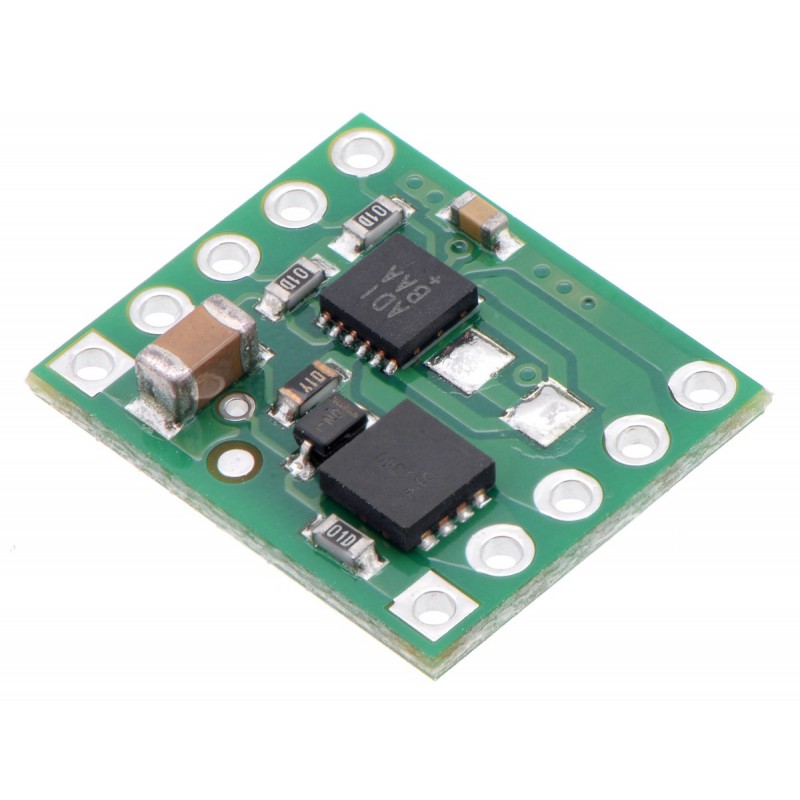

The MAX14870 from Maxim Integrated is a tiny H-bridge motor driver IC that can be used for bidirectional control of one brushed DC motor at 4.5 V to 36 V. It can supply up to about 1.7 A continuously and can tolerate peak currents up to 2.5 A for a few seconds, making it a good choice for small motors that run on a wide range of voltages. The MAX14870 is a great IC, but its small surface-mount package makes it difficult for the typical student or hobbyist to use; our breakout board makes it easy to use with standard solderless breadboards and 0.1″ perfboards. Since this board is a carrier for the MAX14870, we recommend careful reading of the MAX14870 datasheet (492k pdf). The board ships populated with SMD components, including the MAX14870 and a reverse battery protection circuit.

For similar motor drivers that operate at lower voltages, consider our BD65496MUV and DRV8838 motor driver carriers.

Using the motor driverTwo 1×5-pin breakaway 0.1″ male headers are included with the MAX14870 motor driver carrier, which can be soldered in to use the driver with breadboards, perfboards, or 0.1″ female connectors. (The headers might ship as a single 1×10 piece that can be broken in half.) The right picture above shows the two possible board orientations when used with these header pins (parts visible or silkscreen visible). You can also solder your motor leads and other connections directly to the board.

Motor and power connections are made on one side of the board and control connections are made on the other. The driver requires an operating voltage between 4.5 V and 36 V to be supplied to the reverse-protected power input, VIN. The VM pin provides convenient access to the reverse-protected supply voltage.

The MAX14870 offers a simple two-pin DIR/PWM control interface, where the DIR pin determines the motor direction and the PWM pin can be supplied with a PWM signal to control the motor speed. The PWM control input is pulled low on the carrier board through a 100 kΩ pull-down resistor. When the PWM pin is low, the motor outputs are both shorted to ground, which results in dynamic braking of a connected motor.

The EN pin can be driven high to turn off motor outputs, which is useful if you want to let the motor coast. The EN pin is pulled low through a 100 kΩ pull-up resistor on the carrier board so that the driver is enabled by default.

The following simplified truth table shows how the driver operates:

| EN | PWM | DIR | M1 | M2 | operating mode |

|---|---|---|---|---|---|

| 1 | X | X | high-impedance | high-impedance | coast (outputs floating/disconnected) |

| 0 | 1 | 0 | GND | VIN | “reverse” |

| 0 | 1 | 1 | VIN | GND | “forward” |

| 0 | 0 | X | GND | GND | brake low (outputs shorted to ground) |

This carrier board can also be used with Maxim’s MAX14872 motor driver IC, which is a pin-compatible alternative to the MAX14870. The MAX14872 has the same functionality and performance as the MAX14870, but it offers a different control interface. The two parts share the same datasheet (492k pdf), which makes it easy to directly compare the two. If you are looking for a MAX14872 carrier, you can swap out the MAX14870 on one of these boards for a MAX14872 (if you have the appropriate surface-mount rework tools), or we might be able to manufacture a high-volume custom batch for you. If you are interested in this latter option, please contact us.

| PIN | Default State | Description |

|---|---|---|

| VIN | Reverse-protected power supply input; supply this pin with 4.5 V to 36 V. | |

| GND | Ground connection points for the power supply and control signals. The control source and the motor driver must share a common ground. | |

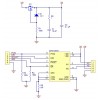

| VM | This pin gives access to the motor power supply after the reverse-voltage protection MOSFET (see the board schematic below). It can be used to supply reverse-protected power to other components in the system. This net connects to the pin labeled “VDD” in the MAX14870 datasheet. | |

| M1 | H-bridge output 1. | |

| M2 | H-bridge output 2. | |

| PWM | LOW | Speed control input; logic high causes the motor to drive. |

| DIR | Direction control input | |

| FAULT | FLOATING | Open-drain, active-low fault output. This pin goes low during an over-current or over-temperature condition. You must use an external pull-up resistor to give this pin a default high value if you want to use it. |

| EN | LOW | Active-low enable input; drive high to tri-state the driver outputs. |

The MAX14870 IC features a SNS input that can be used for optional automatic current limiting. By default, this input is connected to ground on the carrier board, which bypasses the current regulation feature. To enable current limiting, you must first cut the trace between the two unpopulated 1206 resistor pads on the top side of the carrier board.

Then, you will need to add your own appropriate surface-mount 1206 resistor to these pads.

The driver tries to keep the voltage on the SNS pin from exceeding 100 mV, so for example, a 100 mΩ resistor limits the current to 1 A and a 200 mΩ resistor limits it to 0.5 A. For more information on current limiting.

The MAX14870 datasheet recommends a maximum continuous current of 2.5 A. However, the chip by itself will typically overheat at lower currents. In our tests, we found that the chip was able to deliver 2.5 A for only a few seconds before the chip’s thermal protection kicked in and disabled the motor outputs; a continuous current of 1.7 A was sustainable for many minutes without triggering a thermal shutdown.

The actual current you can deliver will depend on how well you can keep the motor driver cool. The carrier’s printed circuit board is designed to help with this by drawing heat out of the motor driver chip. Our tests were conducted at 100% duty cycle with no forced air flow; PWMing the motor will introduce additional heating proportional to the frequency.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

| Size: | 0.6″ × 0.5″1 |

|---|---|

| Weight: | 0.5 g1 |

| Motor driver: | MAX14870 |

|---|---|

| Motor channels: | 1 |

| Minimum operating voltage: | 4.5 V |

| Maximum operating voltage: | 36 V |

| Continuous output current per channel: | 1.7 A2 |

| Peak output current per channel: | 2.5 A |

| Maximum PWM frequency: | 50 kHz |

| Reverse voltage protection?: | Y |

Data sheet

Manufacturer BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Responsible person BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Board with Atmel ATmega328 microcontroller from the AVR family, there are 14 I / O lines, 6 PWM channels and 6 analog inputs. The additional ATmega16U4 microcontroller realizes communication via the USB interface

1000:1 Micro Metal Gearmotor HP

No product available!

The Pololu A-Star 32U4 Prime is a general-purpose programmable board based on Atmel’s ATmega32U4 AVR microcontroller and arranged in the common Arduino form factor exemplified by the Uno R3 and Leonardo. Pololu 3107

Tiny breakout board for TI’s DRV8838 motor driver can deliver a continuous 1.7 A (1.8 A peak) to a single brushed DC motor. Operating voltage range from 0 V to 11 V, built-in protection against reverse-voltage, under-voltage, over-current, and over-temperature. Pololu 2990

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board with soldered connectors. Pololu 5054

No product available!

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board without connectors. Pololu 5053

No product available!

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board with connectors for assembly. Pololu 5052

No product available!

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board with soldered connectors. Pololu 5051

No product available!

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board without connectors. Pololu 5050

No product available!

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board with connectors for assembly. Pololu 5049

No product available!

DC motor driver that allows you to control the movement of two drives using the I2C interface. Board with soldered connectors. Pololu 5048

No product available!

Module of a 4-channel driver of DC motors with RP2040 microcontroller. It allows the connection of encoders and is equipped with a QW/ST connector. Pimoroni PIM636

ESC RC controller module with FlySky receiver. It allows you to control two motors in two directions and one motor in one direction. Dasmigro 2.4G 7CH

Module with a DC motor driver based on the MC33886 chip. It allows you to control the movement of drives with a working voltage from 5 to 28 V and a current of up to 5 A

No product available!

Two-channel ESC controller for brushed motors. It can deliver 40 A and has wires terminated with an XT60 connector

Module with a stepper motor driver based on the DRV8434A system. It allows the bipolar motor to be supplied with current up to 1.2 A per phase and with a voltage from 4.5 V to 45 V. Communication via the SPI interface. Pololu 3769

No product available!

Module with a stepper motor driver based on the DRV8434A system. It allows the bipolar motor to be supplied with current up to 1.2 A per phase and with a voltage from 4.5 V to 45 V. Communication via the SPI interface. Pololu 3768

No product available!

Module with a stepper motor driver based on the DRV8434A system. It allows the bipolar motor to be supplied with current up to 1.2 A per phase and with a voltage from 4.5 V to 45 V. Communication via the SPI interface. Pololu 3767

No product available!

Module with a stepper motor driver based on the DRV8434A system. It allows the bipolar motor to be supplied with current up to 1.2 A per phase and with a voltage from 4.5 V to 45 V. Communication via the SPI interface. Pololu 3766

No product available!

Module with a stepper motor driver based on the DRV8434A system. It allows the bipolar motor to be powered with a current of up to 1.2 A per phase and can be supplied with the voltage from 4.5 V to 45 V. Pololu 3765

No product available!

This compact breakout board for Maxim’s MAX14870 motor driver offers a wide operating voltage range of 4.5 V to 36 V and can deliver a continuous 1.7 A (2.5 A peak) to a single brushed DC motor. It features a simple two-pin speed/direction interface and built-in protection against reverse-voltage, under-voltage, over-current, and over-temperature.