- Out-of-Stock

HP Motor with 48 CPR Encoder for 25D mm HP Metal Gearmotors (No Gearbox)

This is the motor and encoder portion of our high-power (HP) 25D mm metal gearmotors with 48 CPR encoders. It does not include a gearbox, but the pinion gear on the output shaft works with all of our 25D mm gearmotor gearboxes, so this can be used as a replacement motor or encoder for those gearboxes. It is intended for use at 6 V, though it should operate comfortably in the 3 V to 9 V range.

Key specs at 6 V: 9800 RPM and 450 mA free-run, 2 oz-in (0.1 kg-cm) and 6 A stall.

|

This motor with integrated 48 CPR (counts per revolution) quadrature encoder is intended as a replacement high-power (HP) motor and encoder for our 25D mm metal gearmotors. The output shaft has a non-removable pinion gear that works with all of our 25D mm gearmotor gearboxes. Note that we do not sell the 25D mm gearboxes separately, but if you have a gearmotor with a damaged motor or encoder (or if you want to effectively add an encoder to a version without an encoder), you can transfer the gearbox to this replacement motor.

The motor has a diameter of 24.2 mm (0.95 in) and a length of approximately 43 mm (1.7 in) from the top of the motor can to the bottom of the encoder. The top of the motor has two mounting holes threaded for M3 screws. These mounting holes are 17 mm apart and form a line with the motor shaft at the center. The mounting holes have a depth of approximately 6.5 mm.

A lower-power motor with encoder with identical dimensions and an identical pinion gear is also available.

You will typically want to combine this motor with a gearbox to give it a more appropriate combination of torque and speed (without a gearbox, it offers very high speed with very low torque). Our 25D mm line of metal gearmotors consist of this HP motor or a non-HP motor combined with different gearboxes. We do not carry the gearboxes by themselves, so unless you are looking at this as a replacement motor for a compatible gearbox you already have, we strongly recommend you consider getting a preassembled gearmotor with the gear ratio that best suits your project requirements.

| Gear Ratio | No-Load Speed @ 6 V | Stall Torque @ 6 V | Stall Current @ 6 V |  With Encoder |  Without Encoder |

|---|---|---|---|---|---|

| 1:1 | 9800 RPM | 2 oz-in | 6 A | motor without gearbox | |

| 5600 RPM | 1 oz-in | 2.2 A | motor without gearbox | ||

| 4.4:1 | 2220 RPM | 8 oz-in | 6 A | 25Dx48L mm HP | |

| 1280 RPM | 5 oz-in | 2.2 A | 25Dx48L mm | ||

| 9.7:1 | 1010 RPM | 17 oz-in | 6 A | 25Dx48L mm HP | 25Dx48L mm HP |

| 580 RPM | 11 oz-in | 2.2 A | 25Dx48L mm | 25Dx48L mm | |

| 20.4:1 | 480 RPM | 36 oz-in | 6 A | 25Dx50L mm HP | |

| 275 RPM | 24 oz-in | 2.2 A | 25Dx50L mm | ||

| 34:1 | 285 RPM | 60 oz-in | 6 A | 25Dx52L mm HP | 25Dx52L mm HP |

| 165 RPM | 40 oz-in | 2.2 A | 25Dx52L mm | 25Dx52L mm | |

| 47:1 | 210 RPM | 80 oz-in | 6 A | 25Dx52L mm HP | 25Dx52L mm HP |

| 120 RPM | 50 oz-in | 2.2 A | 25Dx52L mm | 25Dx52L mm | |

| 75:1 | 130 RPM | 130 oz-in | 6 A | 25Dx54L mm HP | 25Dx54L mm HP |

| 75 RPM | 85 oz-in | 2.2 A | 25Dx54L mm | 25Dx54L mm | |

| 99:1 | 100 RPM | 160 oz-in | 6 A | 25Dx54L mm HP | |

| 57 RPM | 110 oz-in | 2.2 A | 25Dx54L mm | ||

| 172:1 | 57 RPM | 260 oz-in | 6 A | 25Dx56L mm HP | |

| 33 RPM | 170 oz-in | 2.2 A | 25Dx56L mm | 25Dx56L mm | |

| 227:1 | 25 RPM | 220 oz-in | 2.2 A | 25Dx56L mm | |

| 378:1 | 15 RPM | 250 oz-in | 2.2 A | 25Dx58L mm | |

| 499:1 | 12 RPM | 300 oz-in | 2.2 A | 25Dx58L mm |

Note: At some of the higher gear ratios, these motors can generate enough torque to damage themselves. Any torque greater than about 250 oz-in (18 kg-cm) is likely to damage the gearbox, so we recommend that you avoid stalling the 172:1 HP, 227:1, 378:1, and 499:1 versions of these motors at 6 V.

These motors are intended for use at 6 V. In general, these kinds of motors can run at voltages above and below this nominal voltage, so they should comfortably operate in the 3 – 9 V range, though they can begin rotating at voltages as low as 1 V. Higher voltages could start negatively affecting the life of the motor.

|

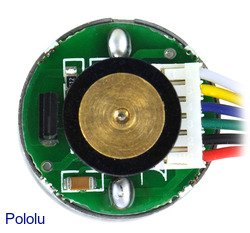

| 25D mm metal gearmotor with 48 CPR encoder: close-up view of encoder. |

|---|

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 48 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 48. The motor/encoder has six color-coded, 11" (28 cm) leads terminated by a 1×6 female header with a 0.1" pitch, as shown in the main product picture. This header works with standard 0.1" male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

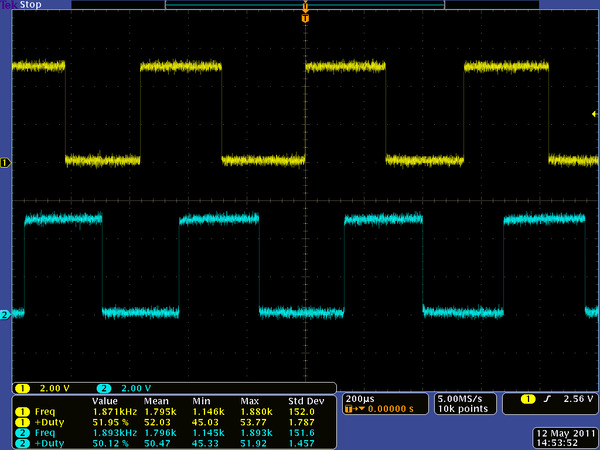

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 6 V and a Hall sensor Vcc of 5 V:

|

| Encoder A and B outputs for 25D mm HP metal gearmotor with 48 CPR encoder (motor running at 6 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 48 counts per revolution of the motor shaft. Using just a single edge of one channel results in 12 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 12 times the motor rotation frequency.

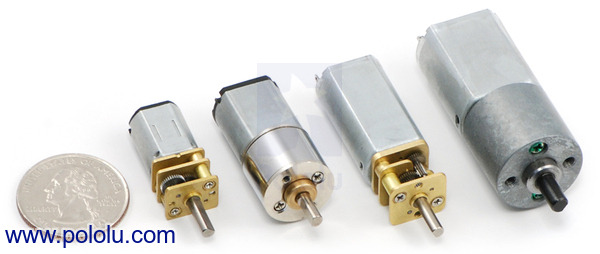

We offer a wide selection of metal gearmotors that offer different combinations of speed and torque. Our metal gearmotor comparison table can help you find the motor that best meets your project’s requirements.

|

| Some of the Pololu metal gearmotors. |

|---|

Data sheet

Manufacturer BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Responsible person BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Module with SSR S208T02 relay with a load up to 4 A. The board is equipped with a Grove connector and is controlled by a digital input. Seeed Studio 103020004

No product available!

Module with a reed relay BR-500Ω with a load up to 0.5 A. The board is equipped with a Grove connector and is controlled by a digital input. Seeed Studio 103020014

No product available!

Module with a 3-axis gyroscope (ITG 3200 system). The measuring range is ± 2000 ° / s. The I2C interface is used for communication. The module has a low power consumption (typically 6.5 mA). The module has a connector in accordance with the Grove standard. Seeed studio 101020050

No product available!

Module module with ADC121C021 12-bit converter. The board is equipped with a Grove connector and communicates via the I2C interface. Seeed Studio 103020013

No product available!

No product available!

No product available!

No product available!

No product available!

Twisted housing, dedicated to the Orange Pi Zero computer. The housing protects the computer against dust, accidental short circuits and mechanical damage. Properly prepared holes allow you to use all the sockets that Orange Pi Zero has been equipped with.

No product available!

No product available!

Banana Pi M2+ is another ARM SoC powered development board that offers great computing performance in an ultra portable form factor. It is a 65mm square with Allwinner H3 Quad-core A7 SoC and 1GB DDR3 RAM

No product available!

Banana Pi camera module for Banana Pi M3, includes CMOS sensor module: OV5640 (5M Pixel)

No product available!

Printed circuit board and programmed AA / AAA cell capacity tester. AVT3169 A +

No product available!

AVT kit for self-assembly of tester capacity AA / AAA cells. AVT3169 B

No product available!

Assembled cell capacitor AA / AAA. AVT3169 B

No product available!

Printed circuit board for water level indicator. AVT1949 A

No product available!

HP Motor with 48 CPR Encoder for 25D mm HP Metal Gearmotors (No Gearbox)