zł80.34 tax excl.

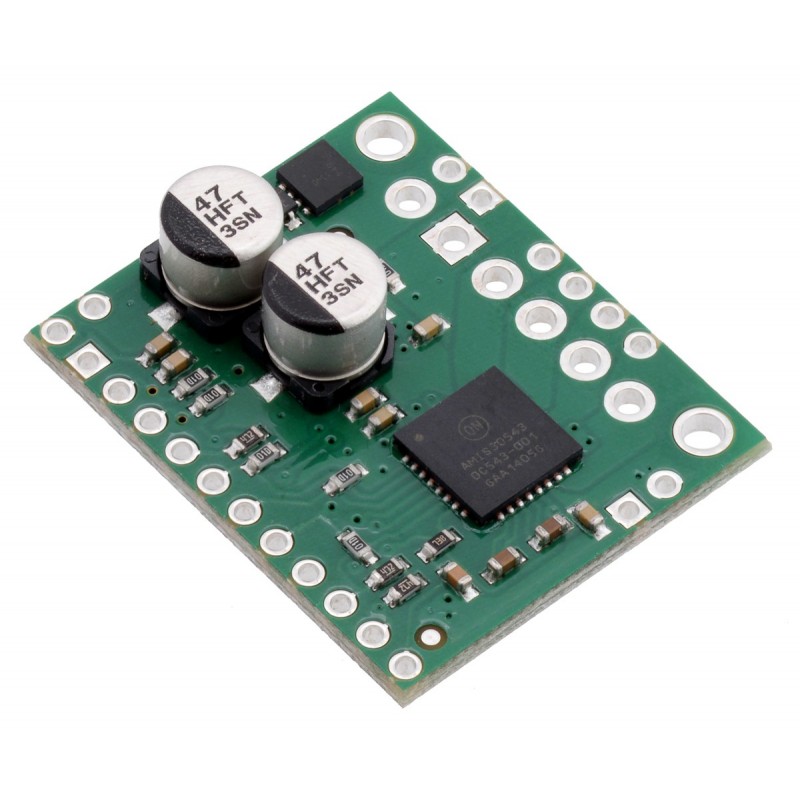

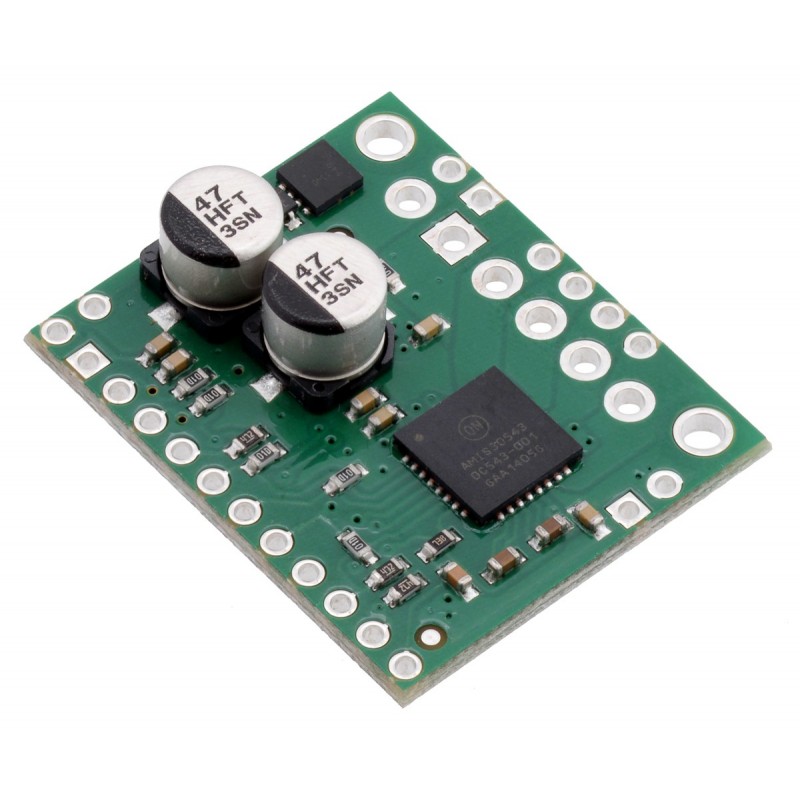

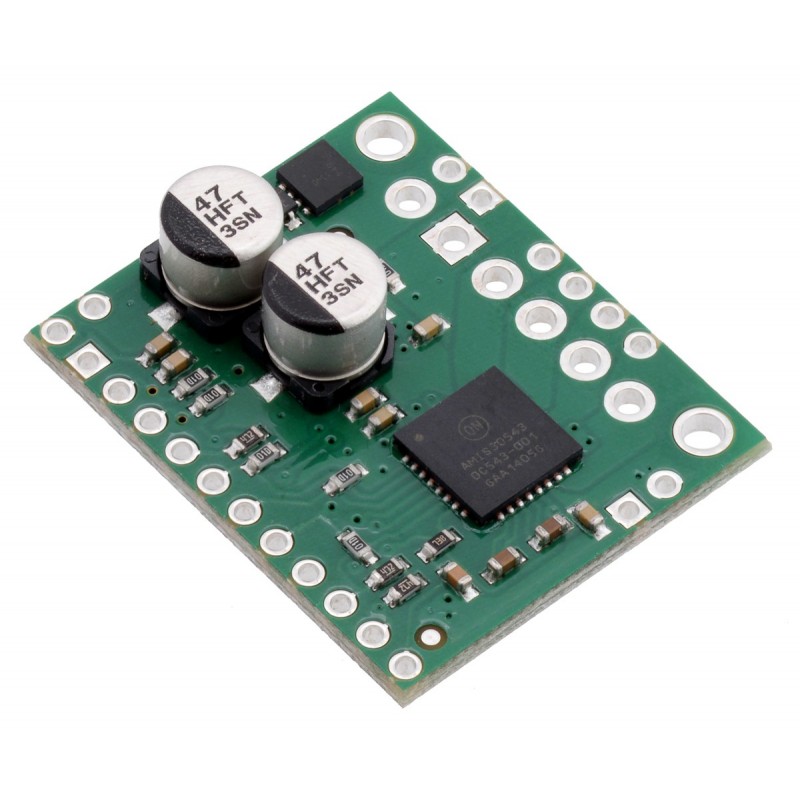

This is a breakout board for ON Semiconductor’s AMIS-30543 microstepping bipolar stepper motor driver, which features SPI-adjustable current limiting, 11 step modes (from full-step through 1/128-step), back-EMF feedback that can be used for stall detection or optional closed-loop control, and over-current and over-temperature protection.

This product is a carrier board or breakout board for ON Semiconductor’s AMIS-30543 Micro-Stepping Motor Driver. This stepper motor driver lets you control one bipolar stepper motor at up to 3 A output current per coil (see the Power Dissipation Considerations section below for more information). Here are some of the board’s key features:

Note: This driver needs to be enabled and configured through its SPI interface on power up, so your microcontroller must be capable of acting as an SPI master (either with an SPI peripheral or software SPI).

This product ships with all surface-mount components—including the AMIS-30543 driver IC—installed as shown in the product picture. However, soldering is required for assembly of the included through-hole parts. The following through-hole parts are included:

The 0.1″ male header can be broken or cut into smaller pieces as desired and soldered into the smaller through-holes. These headers are compatible with solderless breadboards, 0.1″ female connectors, and our premium and pre-crimped jumper wires. The terminal blocks can be soldered into the larger holes to allow for convenient temporary connections of unterminated power and stepper motor wires. You can also solder your motor leads and other connections directly to the board for the most compact installation.

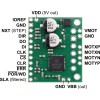

| PIN | Description |

|---|---|

| VMOT | Reverse-protected 6 V to 30 V board power supply connection. Note: Available VDD current is reduced for input voltages under 8 V, and sleep mode is not available for input voltages under 9 V. |

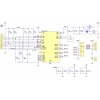

| VBB | This pin gives access to the motor power supply after the reverse-voltage protection MOSFET (see the board schematic below). It can be used to supply reverse-protected power to other components in the system. It is generally intended as an output, but it can also be used to supply board power. |

| GND | Ground connection points for the motor power supply and control ground reference. The control source and the motor driver must share a common ground. |

| MOTXP | Motor output: “positive” end of phase X coil. |

| MOTXN | Motor output: “negative” end of phase X coil. |

| MOTYP | Motor output: “positive” end of phase Y coil. |

| MOTYN | Motor output: “negative” end of phase Y coil. |

| VDD (5V OUT) | The board is powered by an internal 5V regulator, and this pin gives access to the regulated 5 V output. This can be used to supply the neighboring IOREF pin when using this board in 5V systems, and it can be used to power an external microcontroller. When VMOT is over 8 V, approximately 30 mA is available for external components; when VMOT is less than 8 V, the available current drops to less than 10 mA. |

| IOREF | All of the board signal outputs (except SLA) are open-drain outputs that are pulled up to IOREF, so this pin should be supplied with the logic voltage of the controlling system (e.g. 3.3V for use in 3.3V systems). For convenience, it can be connected to the neighboring VDD pin when it is being used in a 5V system. |

| NXT | Changes on this input move the motor current one step up or down in the translator table (even when the motor is disabled). The edge that triggers the step depends on the NXT-polarity configuration bit, which can be changed through the SPI interface (rising edge by default). |

| DIR | Input that determines the direction of rotation. The direction can also be controlled through the SPI interface. |

| DO | SPI data output. (This pin is also often referred to as “MISO”.) |

| DI | SPI data input. (This pin is also often referred to as “MOSI”.) |

| CLK | SPI clock input. |

| CS | SPI chip select input. Logic transitions on this pin are required for SPI communication, even if this is the only device on the SPI bus. |

| CLR | Chip reset input. A logic high on this input clears all internal registers, except in sleep mode. |

| ERR | Error output. This pin drives low to indicate that an error condition has occurred. The specific error can be determined by using the SPI interface to check the error flags. |

| POR/WD | Power-on reset/watch dog function output. This pin provides an active-low signal that can be used as a reset input for an external microcontroller. |

| SLA (filtered) | SLA (speed and load angle) output after a low-pass filter. The result is an analog voltage between 0 V and 5 V that indicates the level of the back-EMF voltage of the motor. This signal can be used for stall detection or closed-loop control of the torque and speed based on the load angle. Note: Since the output of this pin ranges from 0 V to 5 V regardless of IOREF, extra precautions should be taken when connecting this pin to a 3.3V device (such as passing it through an appropriate voltage divider). |

If you are new to the AMIS-30543 or stepper motors in general, our AMIS-30543 Arduino library can help you get started. The library provides basic functions for configuring and operating the driver using an Arduinoor Arduino-compatible controller. It also provides access to many of the driver’s advanced features and includes example sketches that show you how to use them.

The AMIS-30543 driver IC has a maximum current rating of 3 A per coil, but the actual current you can deliver depends on how well you can keep the IC cool. The carrier’s printed circuit board is designed to draw heat out of the IC, but to supply more than approximately 1.8 A per coil continuously, a heat sink or other cooling method is required. However, it is possible to use the SPI-configurable current limit to selectively deliver higher currents than this for short durations without overheating the driver.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

Please note that measuring the current draw at the power supply will generally not provide an accurate measure of the coil current. Since the input voltage to the driver can be significantly higher than the coil voltage, the measured current on the power supply can be quite a bit lower than the coil current (the driver and coil basically act like a switching step-down power supply). Also, if the supply voltage is very high compared to what the motor needs to achieve the set current, the duty cycle will be very low, which also leads to significant differences between average and RMS currents.

| Size: | 1.0″ × 1.2″ |

|---|---|

| Weight: | 4.0 g1 |

| Minimum operating voltage: | 6 V2 |

|---|---|

| Maximum operating voltage: | 30 V |

| Continuous current per phase: | 1.8 A3 |

| Maximum current per phase: | 3 A4 |

| Minimum logic voltage: | 2.5 V |

| Maximum logic voltage: | 5.5 V |

| Microstep resolutions: | full, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128 |

| Reverse voltage protection?: | Y |

Data sheet

Manufacturer BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Responsible person BTC Korporacja sp. z o. o. Lwowska 5 05-120 Legionowo Poland sprzedaz@kamami.pl 22 767 36 20

Bipolar stepper motor. It has a resolution of 200 steps/revolution (1.8° per step), a rated voltage of 3.9 V, and draws a current of 0.6 A per coil. Pololu 1204

Bipolar stepper motor. It has a resolution of 200 steps/revolution (1.8° per step), has a nominal voltage of 4 V and draws a current of 1.2 A per coil. Pololu 1200

Unipolar/bipolar stepper motor. It has a resolution of 200 steps/revolution (1.8° per step), has a nominal voltage of 8.6 V, and draws a current of 1 A per coil. Pololu 1477

No product available!

Dual MAX14870 Motor Driver is a dual DC driver compatible with Raspberry Pi that allows you to control two DC motors with 4.5-36V continuous current of 1.7A. Pololu 3759

ual MAX14870 Motor Driver is a dual DC motor driver compatible with the Raspberry Pi standard that allows you to control two DC motors with 4.5 ... 36V continuous current of 1.7A. Pololu 3758

This powerful motor controller makes closed-loop speed or position (but not both!) control of a brushed DC motor easy, with quick configuration over USB using our free software. It supports five control interfaces: USB, TTL serial, I²C, analog voltage (potentiometer), and hobby radio control (RC).

DC motor driver with voltage 6.5 ... 40V and maximum continuous current 13A. It has the ability to easily implement the feedback loop and numerous control interfaces. Polol 3147

DC motor driver with voltage 6.5..30V and maximum continuous current 27A. It has the ability to easily implement the feedback loop and numerous control interfaces. Polol 3148

No product available!

DC motor driver with voltage 6.5..40V and maximum continuous current 21A. It has the ability to easily implement the feedback loop and numerous control interfaces. Polol 3149

No product available!

The controller enables to supply the motors with voltage in the range of 10-47V and power consumption in continuous operation of 1.7A (4.5A peak) for each channel in dual or 3.4A mode (9A peak) in single channel mode. Pololu 2999

TB9051FTG Single Brushed The DC Motor Driver Carrier is a single DC motor driver that allows the motor to be supplied with voltage in the 4.5 ... 28V range and power consumption at a continuous 2.6 A (5A peak) operation. Pololu 2997

DC motor driver module with two channels, dedicated to use in modeling. It can be controlled by an RC transmitter and uses the PPM signal. DFRobot DFR0513

TB67S279FTG stepper motor controller module supplied with 10 ... 47V voltage and 1.2A working current. The controller allows you to control the motor movement up to 7 different resolutions (up to 1/32 of a step). Pololu 2974

TB67S249FTG stepper motor driver module supplied with 10-47V voltage and working current of 1.7A. The controller allows you to control the motor movement up to 7 different resolutions (up to 1/32 of a step). Pololu 2973

The expansion module is designed to work with micro:bit. It allows you to control 4 DC motors or two stepper motors and 8 servos. It communicates via the I2C interface. DFRobot DFR0548

The X-NUCLEO-IHM16M1 motor driver expansion board is based on the STSPIN830 monolithic driver for three-phase brushless motors. It represents an affordable, easy-to-use solution for driving brushless motors in your STM32 Nucleo project, implementing single and three-shunt current sensing

Dual DC motor controller designed for Arduino, which enables the motor to be supplied with voltage in the 4.5 ... 28V range and power consumption in continuous operation of 2.6 A (5A at the top) of two DC motors. Polol 2520

Dual DC motor controller designed for Raspberry Pi, which enables the engine to be supplied with voltage in the 4.5-28V range and power consumption in continuous operation of 2.6A (5A in peak) of two DC motors. Pololu 2762

Dual DC motor controller designed for Raspberry Pi, which enables the engine to be supplied with voltage in the 4.5-28V range and power consumption in continuous operation of 2.6A (5A in peak) of two DC motors. Self-assembly set. Pololu 2761

This is a breakout board for ON Semiconductor’s AMIS-30543 microstepping bipolar stepper motor driver, which features SPI-adjustable current limiting, 11 step modes (from full-step through 1/128-step), back-EMF feedback that can be used for stall detection or optional closed-loop control, and over-current and over-temperature protection.